Horisontal TLC chamber for TANK and Sandwich methods

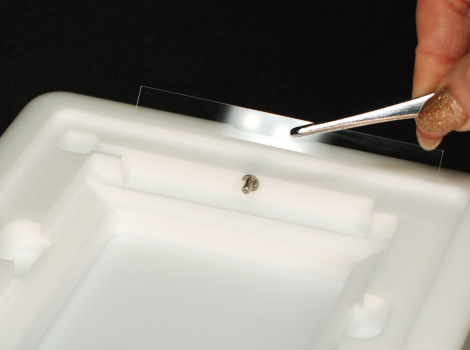

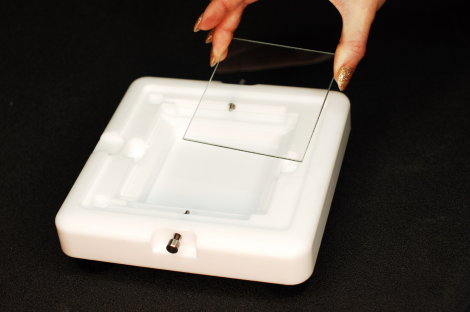

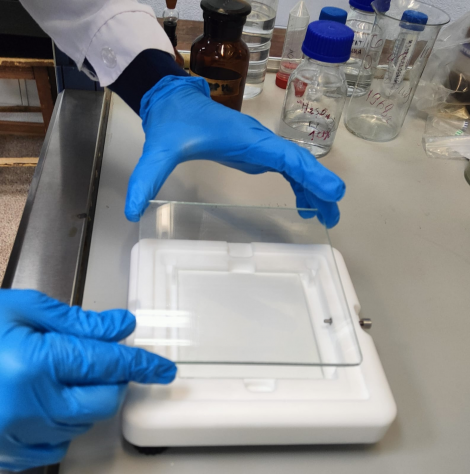

Modern HPTLC chamber for effective eluation of plates, can perform with all types of elutants; to minimize the influence of ambient conditions and reduce pollution and smells the chamber is covered with glass lid in pre- conditioning stage and during plate development process. It starts by pushing stainless steel rods at the two oposite sides of device.

TLC plate is put inside th central capacity on supports on edges. Sorbent layer should be positioned downwards;

The device can be leveled horisontally by rotation of three supports with thread, to guarantee even distribution of elutant;

Tempered glass is used in starting line strips;

All body is manufactured from massive Teflone brick.;Basement and glass pushers are made of stainless steel;

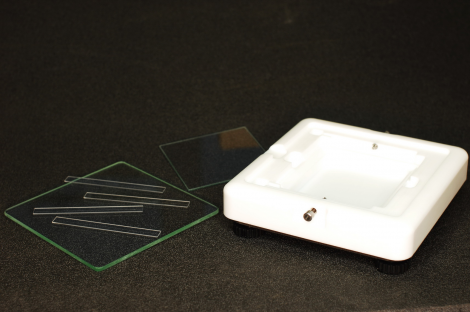

Extra glass plates are included in the set of delivery.

Size of TLC (HP TLC) plate used 100 x 100 mm

Dimentions 160 x 140 x 60 mm

Weight 2.5 kg

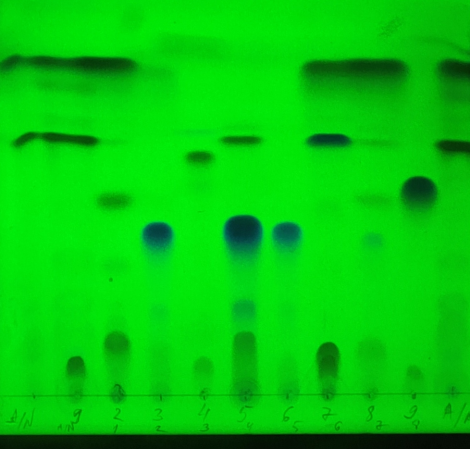

Plate is developed from two sides at once, doubling the number of separeated samples. Performing HPTLC process (High-Performance Thin Layer Chromatography) at 100X100 mm glass or Al- based plates - is the main purpose of this device ( FLATEL-S1 Chamber). It gives the laboratory an opportunity to perform two eluation proceses at once. The TANK mode and SANDWICH mode are realized.